The Rise of Alternative Procurement in Marine Construction

Collaborative contracting models in the marine construction industry, commonly referred to as Alternative Procurement, are reshaping project delivery in our industry by fostering innovation, enhancing efficiency, and improving risk allocation between clients and contractors. These Early Contractor Involvement (ECI) procurement approaches like Design-Build (DB) contracts are becoming increasingly common due to proven advantages such as schedule compression, reduced changes, and enhanced potential for value engineering compared to traditional methods.

These contracting methods are specifically designed to foster early contractor involvement in the project planning, permitting and design phases and to diverge from traditional contracting methods where contractors have been selected based solely on the lowest bid. They succeed by empowering project owners and stakeholders with significant input and control over early project design decisions, potentially leading to a more efficient and cost-effective project execution.

Several other increasingly common Alternative Procurement methods akin to Design-Build (DB) include Progressive Design-Build, (PDB) Construction Manager General Contractor (CMGC), Construction Manager at Risk (CMAR), Best Value, and Low Price Technically Acceptable (LPTA). These contracting models work best because they put early emphasis on identifying and managing the complexities of large-scale projects, especially in the marine sector where challenges like environmental variables and heightened safety risks are prevalent.

According to Mike Edde, Vice President of Estimating at The Dutra Group, “Involving the contractor during the design and permitting process allows the project owner to develop designs with realistic contractor means and methods in mind. Without early contractor involvement, sometimes the permit applications do not consider constructability and they need to be resubmitted after the contractor is brought on board to ensure the project can be built. This has the potential to add delays to the project schedule, increase cost of the project, and increase the overall risk to the owner.”

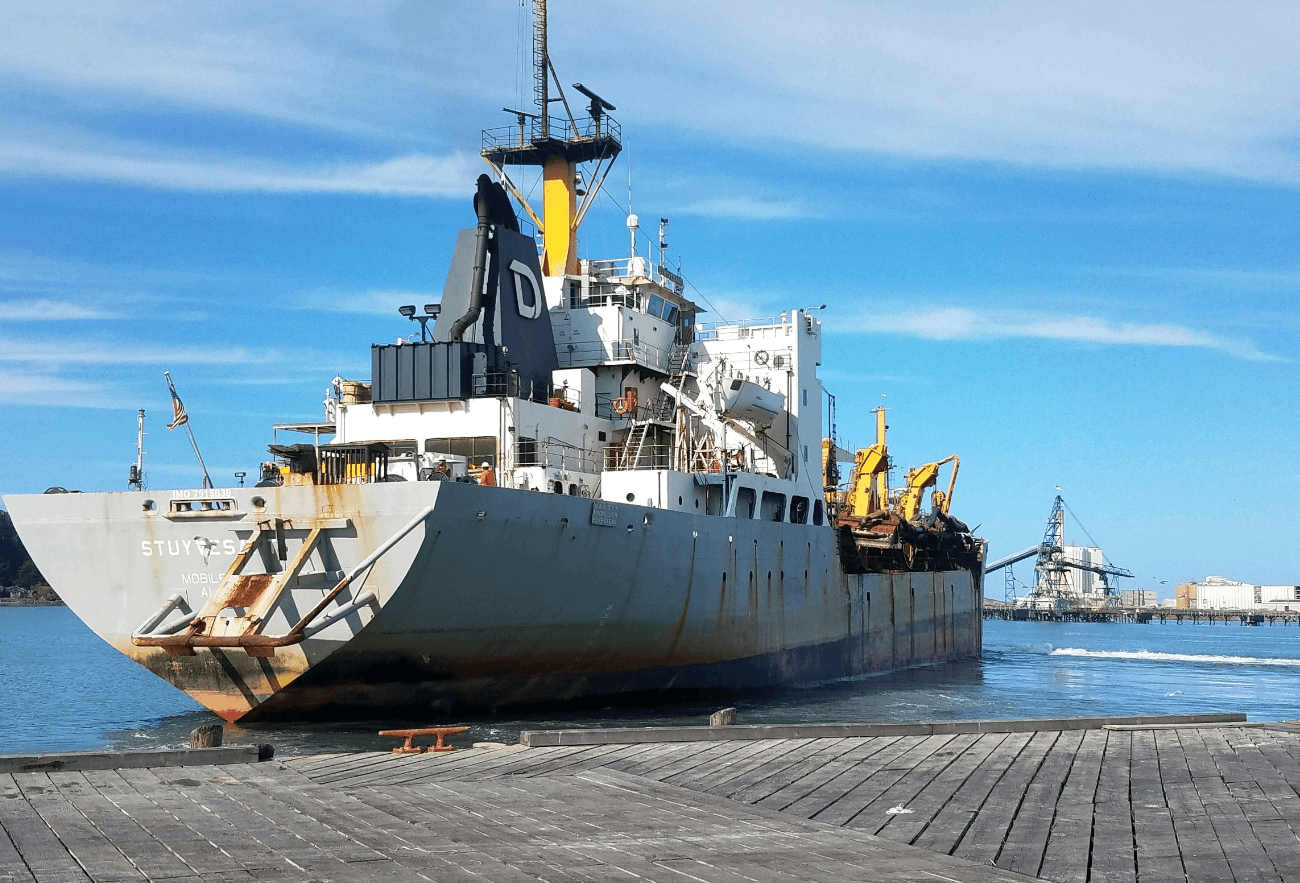

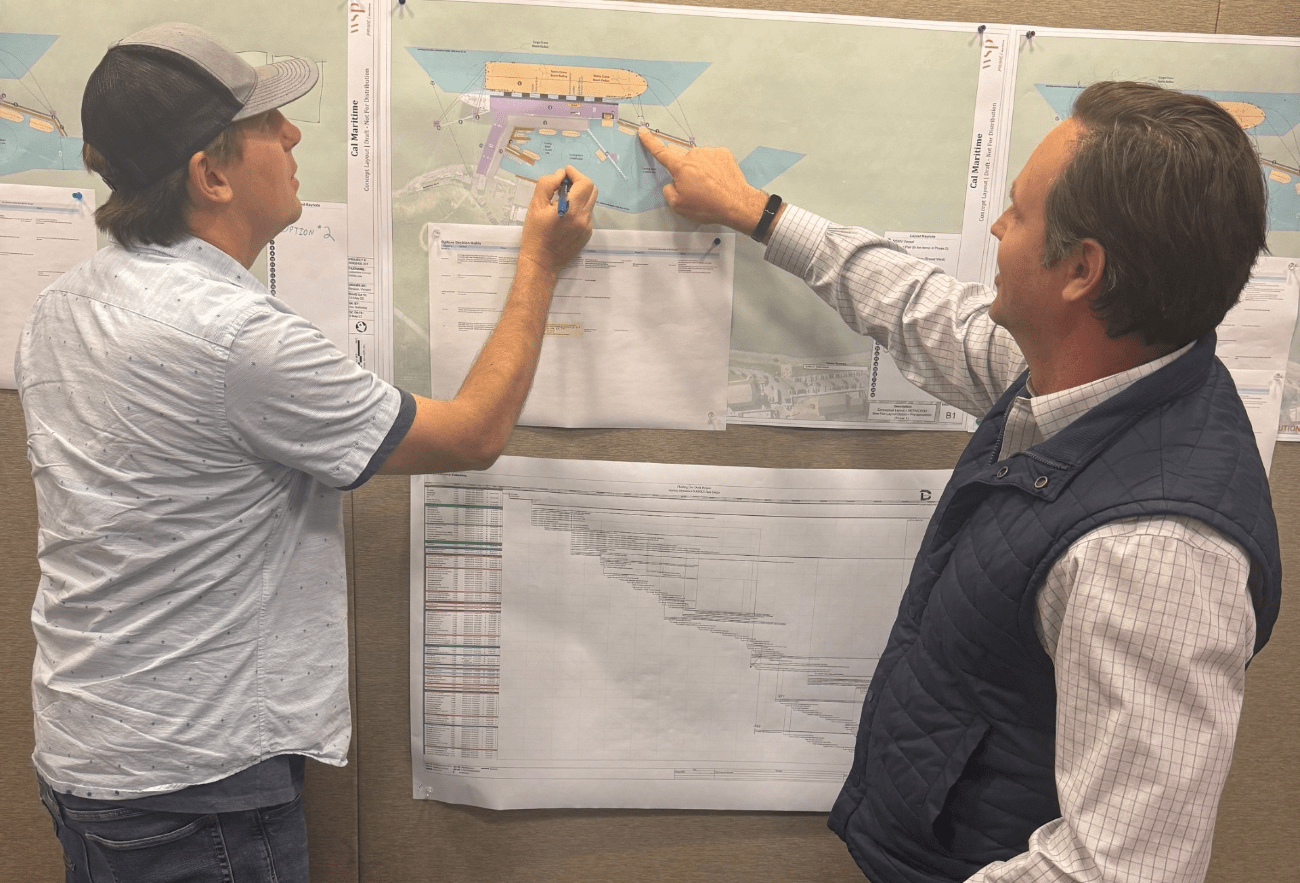

As an example, Mike highlights Dutra’s current Boat Basin and Pier Extension Project for California State University Maritime (Cal Maritime) situated along the Carquinez Strait in Vallejo, California. This Progressive Design Build (PDB) project will enable Cal Maritime to replace the 37-year-old Golden Bear Training Ship with a new National Security Multi-Mission Vessel (NSMV) at the University’s pier facilities as early as 2026. This project is Phase 1 of the University’s Waterfront Masterplan to extend the existing pier, add mooring capability for the new larger vessel, and improve fendering and wave screens for the boat basin. The new NSMV will be the primary training vessel at Cal Maritime and will also serve as an emergency response vessel for humanitarian assistance and disaster relief.

The project is still in its early stages known as preconstruction or preliminary services, where the focus is on budget-level design development and negotiating a firm contract price for the construction phase. This collaborative phase ensures that the project’s design meets the owner’s requirements through ongoing transparent cost estimates as the design is being developed. The subsequent construction phase encompasses final design, construction, and commissioning.

The Dutra Group has also successfully performed a recent Construction Manager/General Contractor (CMGC) project. The owner was a private developer who had hired a marine engineer to gather some initial design concepts. Given the complexity of the project, the owner sought to use the CMGC format to get a trusted and experienced contractor on board well in advance of final design to work alongside the design team to create buildable seawall concepts within the owner’s budget. Dutra provided some initial budgetary estimates and technical write-ups. Interviews of several potential CMGCs were conducted by the Owner and Engineer, and ultimately, Dutra was the selected CMGC.

Once on board, the Dutra team met on a weekly basis with the Owner and Designer to help narrow down design concepts. This iterative process led to several design concepts being compared and contrasted by the owner. Dutra provided cost estimates for each design concept and helped steer the owner to choose the best concept that fit the budget and project schedule. Ultimately, this complex project was delivered within the owner’s budget and on schedule. Several different seawall designs were used due to the changing site conditions along the shoreline. If a traditional approach (low bid) was used for this project it would have likely resulted in a longer construction duration, higher project costs, and lots of change orders.

Another notable alternative procurement project completed by Dutra is the WETA North Bay Operation and Maintenance Facility. This project involved the construction of a new facility to support the operation and maintenance of the Water Emergency Transportation Authority’s (WETA) ferry fleet in Vallejo, CA. The project’s success was attributed to the Design-Build procurement method, which facilitated a seamless integration of design and construction processes, allowing for a more efficient and timely completion of the facility. This approach not only ensured the project met its operational requirements but also adhered to budgetary constraints and schedule timelines.

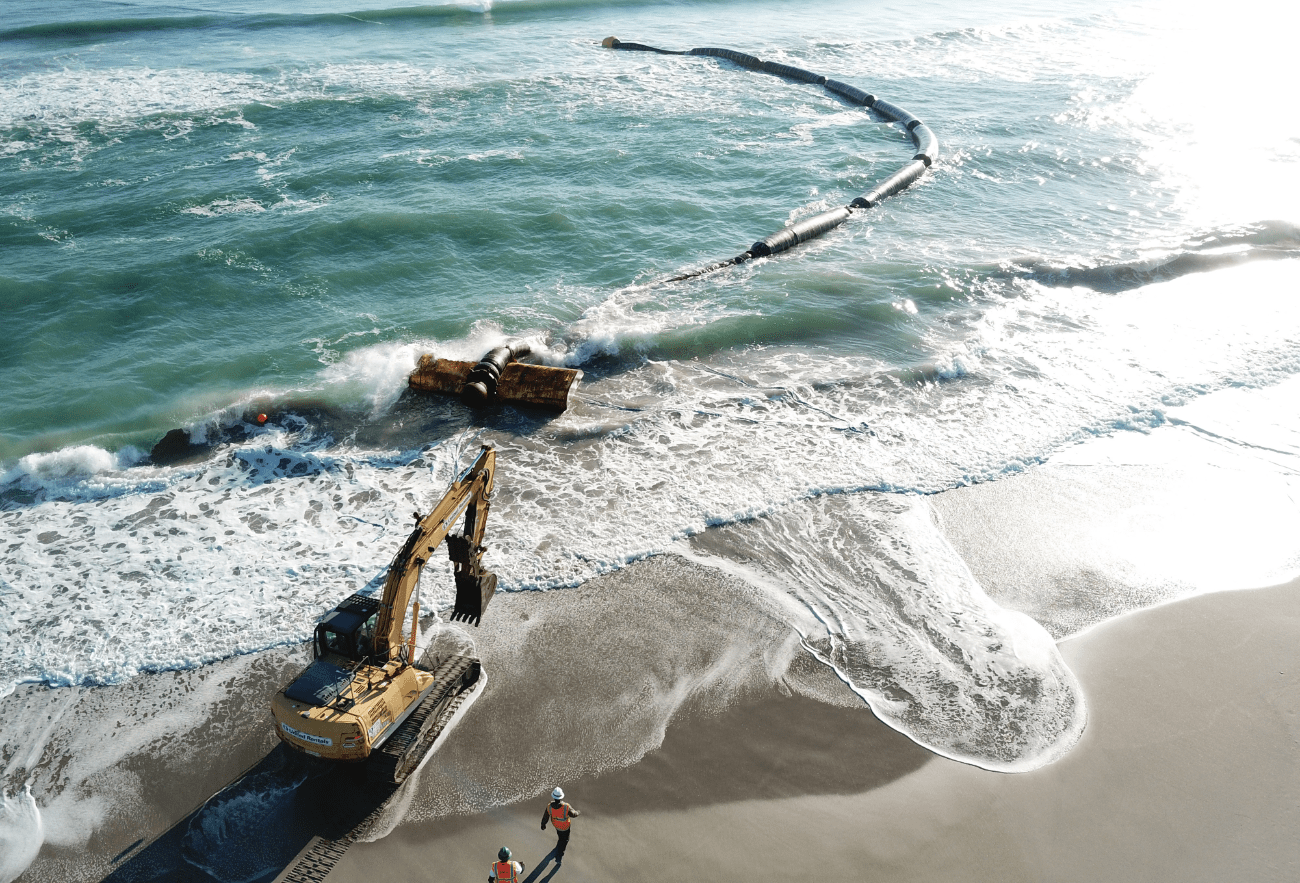

A third example of an alternate procurement project completed by Dutra is The San Francisco Marina West Harbor Renovation Project. The Design-Build approach on this project allowed Dutra to partner with the owner to adopt a phased approach, enabling the continued use of the marina throughout the construction project. This early collaboration with all stakeholders (the owner, engineer, contractor, harbormaster, and boaters) was crucial. Without it, the project would have necessitated the closure of the marina during construction and the relocation of many more boats to other marinas. This strategy resulted in a win-win solution that minimized impact on the marina’s ongoing operations during construction.

The success of past projects like these demonstrates the advantages of alternative procurement methods over traditional approaches, highlighting elevated levels of collaboration, innovation, and operational efficiency.